Gear construction specialists

and mechanical processing

Our Rosate workshop has been operating in the mechanical processing sector for over sixty years: with a state-of-the-art machine park we carry out milling and turning, toothing and grinding services, for mass production and single processing.

Thanks to the experience gained in over 60 years of activity and the use of cutting-edge procedures and machinery, we are able to deal with any kind of customer request promptly and accurately.

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

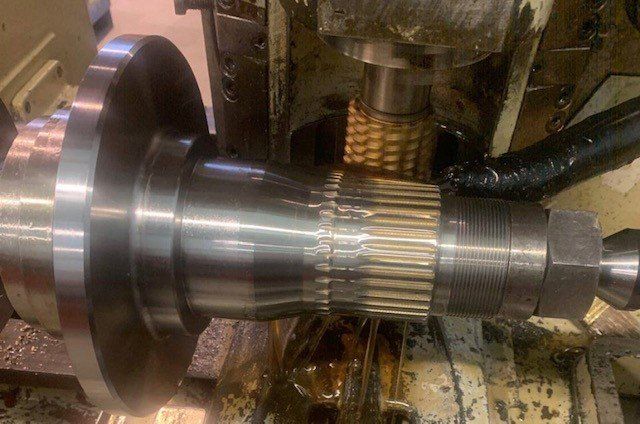

Turning and milling

Our turning department is equipped with numerically controlled lathes

and cnc machining centers.

We create parts according to drawings or samples, as needed,

for single pieces and for mass production up to diameter 1000.

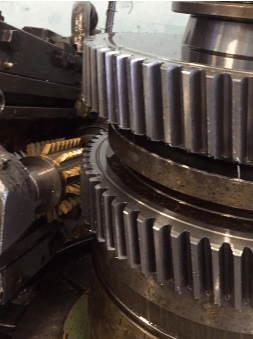

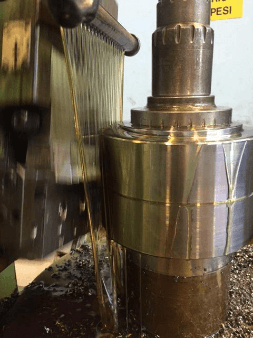

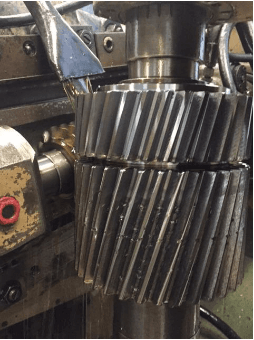

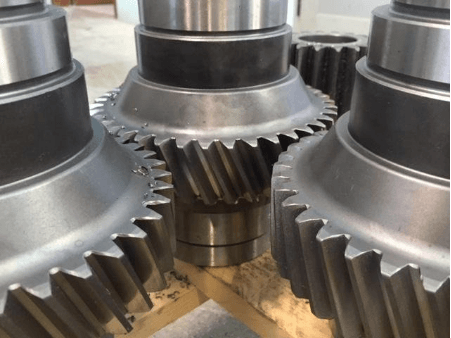

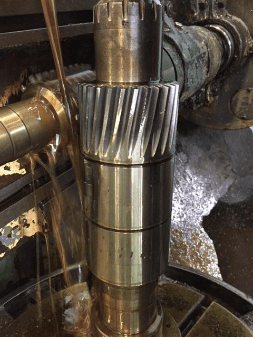

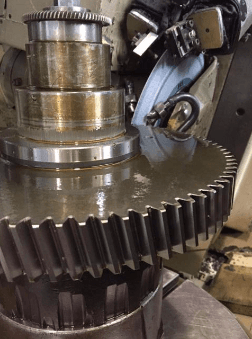

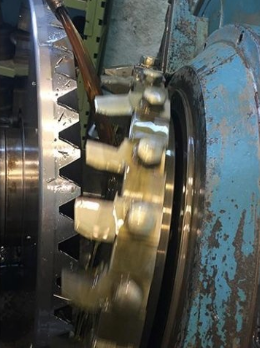

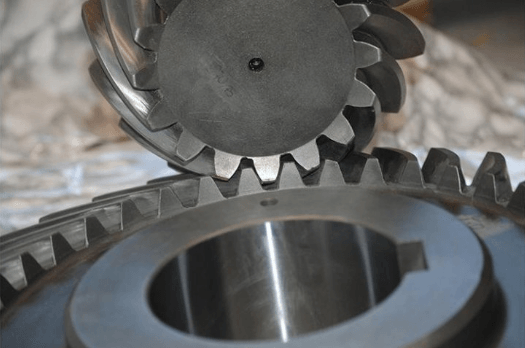

Hobbing

Our hobbing department includes hobbing and comb hobbing machines.

We produce hobbing and comb toothing from module 1.5 to 14.

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

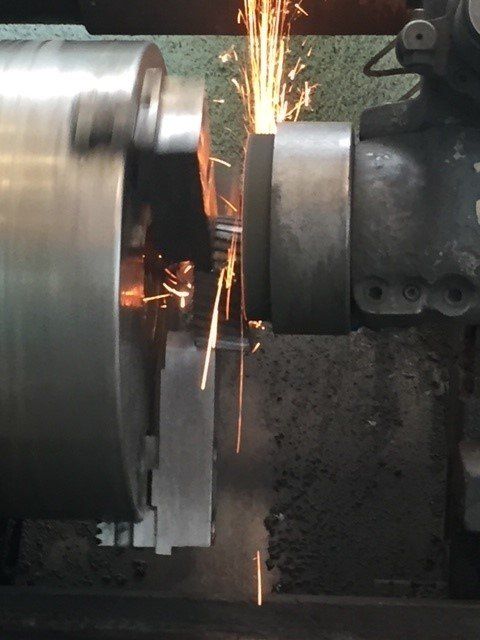

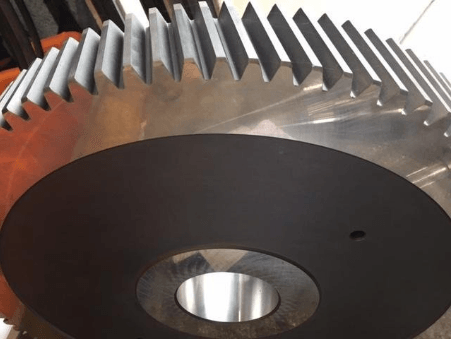

Involute and diameter grinding

Grinding is the last part of the production process: our department carries out grinding operations on gears up to 900 in diameter.

A new numerical control grinding has been introduced in the department, equipped with an evolventimeter to certify the quality.

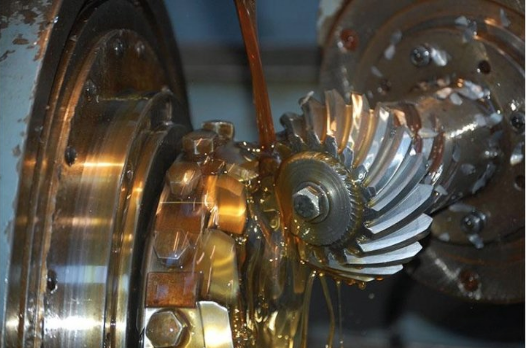

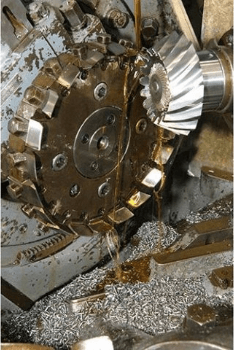

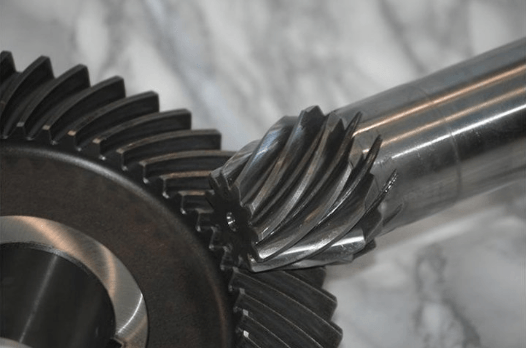

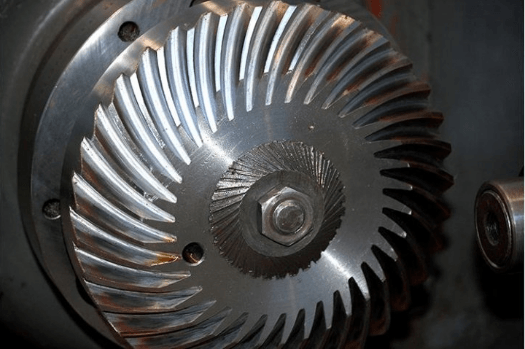

Spiral pairs

Spiral bevel gears up to a diameter of 900 mm: we produce Gleason spiral bevel gears up to Module 20 and Klingelnberg transformations while maintaining the transmission ratio and overall dimensions.

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

Slide title

Scrivi qui la tua didascaliaButton

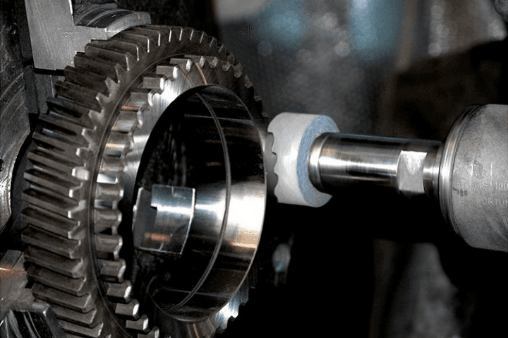

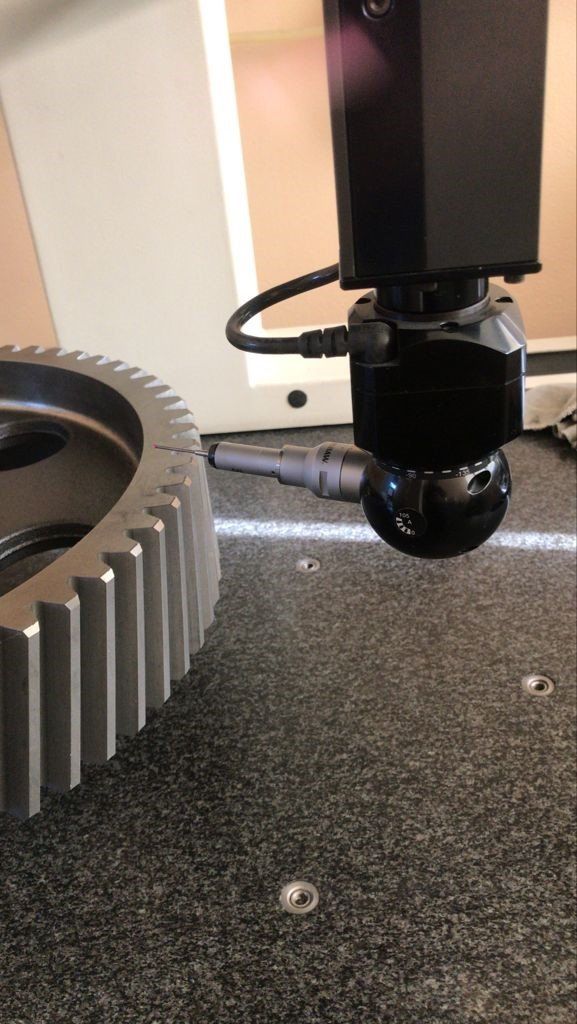

Dimensional control

with Dea luminaire

The products of our company are subject to rigorous controls both during all the production phases and at the end of the same, guaranteeing strict compliance with the quotas indicated in the drawing by means of detection with a 3d device in the air-conditioned room.

Always up to date on the latest innovations proposed by the market and equipped with a very helpful and qualified staff, our company has established itself as a reference reality in the sector of the production of gears and mechanical applications in general.